A Concentric Coupling is used to connect seal bore extensions to increase length.

The Half Mule Shoe Guide is standard with the Seal Assembly to allow for easy entry into the packer bore.

The Hydraulic Permapak Packer is a hydraulic set seal bore packer and is the hydraulic set equivalent of the Permapak Seal Bore Packer.

When a Knock-Out Bottom is run below the packer, the knock-out plug allows a packer to serve as a bridge plug holding pressure from above and below.

The Locator Seal Assembly is used in installations which require floating seals.

A Mill-Out Extension is used in installations where floating seals are required due to tubing contractions.

The Dual Bore Permapak Packer is a highly versatile packer which has a large upper sealbore to allow for a large bore through the packer.

The Permapak Seal Bore Packer can be used for single or multiple zone completions.

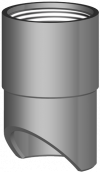

A Seal Bore Extension is used in installations where floating seals are required due to tubing contractions.

A Seal Bore to Mill-Out Coupling is used to connect mill-out extensions to seal bore extensions.

The standard Seal Unit is furnished with bonded nitrile rings and a 12-inch make-up length.

The Snap Latch Seal Assembly latches into the packer upon set down (like our Anchor Latch Seal Assembly).

A Wireline Re-Entry Bottom is used as the packer bottom when an extension below a packer is not required.

The Wireline Adapter Kit (WLAK) – for Permapak Packer is designed to set Permapak Seal Bore Packers with industry standard wireline pressure setting assemblies or comparable equipment.